If you manage trackways, you know this set of problems all too well: squealing on curves, accelerated wear and tear of wheel flanges and railheads, mounting maintenance costs, complaints from residents and pressure to “do something about it” – preferably quickly and without further interference that will hinder operation.

The truth is: most lubrication solutions work… as long as someone takes care of them. And in the real world of infrastructure maintenance, “until” is sometimes short. That’s why Innotechnika has developed an automatic retractable streetcar lubricator: a device that is supposed to do its job regularly, precisely and without daily maintenance – without protrusions and without compromising safety.

Why grease the switches and rails in the curves at all?

Lubrication is not cosmetic. It’s a tool to control friction where infrastructure gets the most bite:

- Crossovers – dynamic loads, operation of moving parts, risk of increased resistance and faster wear,

- Curves and turnouts – contact between the wheel flange and the rail can generate noise and intense abrasion,

- Acoustically sensitive places – dense buildings, bus stops, sections in city centers.

Without stable lubrication, you pay three times: noise, wear and tear, and emergency service.

What’s different about Innotechnika’s lubricator?

Innotech has gone in a direction that makes operational sense: a device hidden beneath the track surface.

That means specifics:

- No interference with track space (nothing sticks out, nothing tempts vandals, nothing impedes passage or maintenance).

- Higher driving comfort and safety, because lubrication is done predictably and in a controlled manner.

- Protection of the device from the environment, because the whole works in a specially designed well.

This is not a “gadget,” but a design decision that solves a typical conflict: lubrication is necessary, but it is not allowed to add another obstacle to the track.

How it works: automation that’s really meant to ease the maintenance burden

Innotechniki’s automatic tramway lubricators are designed as fully automated devices for unmanned lubrication:

- crossovers,

- rails in curves,

- track infrastructure turnouts.

The system dispenses grease precisely in two ways (depending on the configuration):

- Based on the number of passes – rail vehicles are detected by the sensor, and the lubricant is administered according to the real traffic,

- at fixed time intervals – when operating conditions require it.

The most important thing is that the lubricant does not fly “by eye”. It is administered when it makes sense.

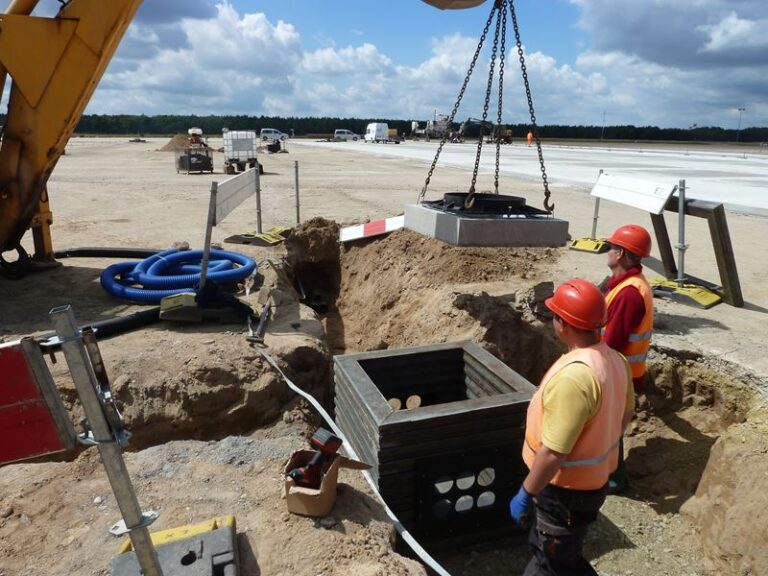

Installation below the surface: well + service elevator = access without risk of flooding

The device is mounted below the track surface, in a specially designed well with a service elevator. This solution does two things at once:

- provides easy service access (no unbolting, no improvisation),

- protects the device from flooding (in practice: less downtime and fewer unplanned interventions).

What matters in infrastructure maintenance is not just “whether it works,” but also “whether it can be serviced quickly and safely.” The service elevator is the answer to precisely this daily logistics.

For whom does this solution make sense?

If you have even one of these situations, the topic is for you:

- Curved sections with increased noise,

- Intensive crossovers,

- Turnouts in areas where service access is difficult,

- places prone to vandalism (hiding the device realistically reduces the risk),

- Sections requiring reduced track interference.

Feel free to contact us!